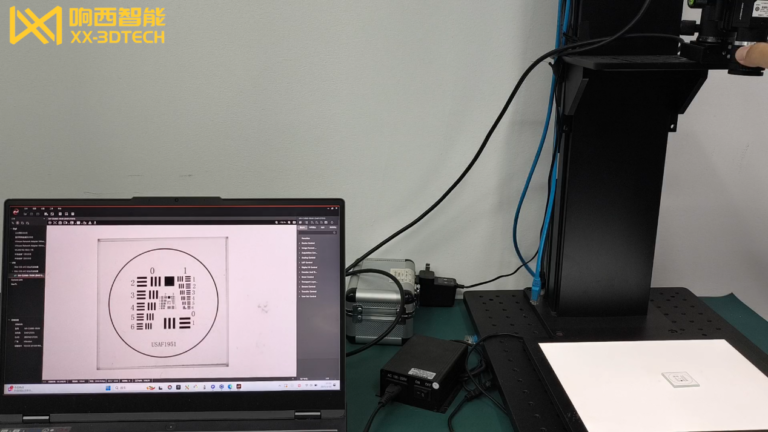

In modern industrial inspection and 3D scanning for dimensional modeling, industrial 3D scanners and 3D inspection machines have become essential tools. These devices provide precise data support for industrial inspections, and at the heart of these machines lies the industrial camera lens. The lens choice and its configuration directly impact image quality and inspection accuracy. Today, we’ll break down the key parameters of industrial camera lenses, along with 3D printing tips, to help you make more informed decisions when selecting the right lens for your needs.

Focal Length: Determining the Field of View (FOV)

When selecting an industrial camera lens, focal length is one of the most crucial parameters. It determines the lens’s field of view (FOV), or the area the lens can capture. For industrial 3D scanners and 3D inspection machines, choosing the right focal length is essential for matching the size of the area you need to capture. If the focal length is too short, you might experience distortion at the edges of the image. On the other hand, if the focal length is too long, it may not cover a large enough detection area.

For applications like 3D printing, achieving the right balance in focal length is key to capturing accurate details and minimizing errors in the final model. Whether you’re working on industrial inspections or looking for 3D printing tips, selecting the correct focal length is the first step toward ensuring high-quality imaging.

Aperture: Impacting Scene Adaptability

The aperture determines how much light the lens can capture, directly influencing exposure levels. The larger the adjustable aperture range, the more adaptable the lens is to different environments. For 3D printing and dimensional modeling, it’s recommended to choose lenses with a wide aperture range, ideally with an aperture value of F2.0 or smaller. Whether you’re in a complex industrial workshop or working in low-light conditions, these lenses will provide sufficient exposure to ensure high-quality imaging.

For those seeking 3D printing tips, proper aperture selection also plays a role in capturing precise details for accurate modeling.

Sensor Size: Matching the Camera Sensor

3D printing tips also emphasize the importance of sensor size when selecting an industrial camera lens. Sensor size refers to the maximum image sensor size the lens can cover. When choosing an industrial camera lens, the sensor size must match the camera’s sensor size and be no smaller than the camera’s requirements. A lens with a sensor size that’s too small may cause black edges or blurriness at the image’s borders.

For 3D inspection machines and industrial 3D scanners, selecting the right sensor size is crucial for maintaining image integrity.

Pixel Count: Determining Imaging Resolution

Pixels measure the lens’ resolution, typically expressed in megapixels (MP). For 3D printing and modeling, your lens’s pixel count should meet or exceed the camera’s pixel requirements — the higher, the better. A higher pixel count helps capture more details, improving the accuracy of your 3D models. Especially for high-precision industrial inspections, lenses with more pixels ensure clearer imaging, keeping your inspection data precise.

Depth of Field: Defining Focus Range

Depth of field is also one of the key aspects you need to master in 3D printing tips. Depth of field refers to the range where the image remains sharp after the object is focused. The larger the depth of field, the greater the area in focus. For industrial 3D scanners and 3D inspection machines, a larger depth of field is ideal — particularly when scanning complex shapes.

A larger depth of field ensures that every part of the object remains in focus. Depth of field is also influenced by the aperture size; the smaller the aperture, the greater the depth of field.

Distortion: Affecting Imaging Accuracy

Optical distortion refers to the degree of deformation in the image caused by the lens. The less distortion, the higher the imaging accuracy. This is especially important in 3D printing and modeling, where excessive distortion can lead to data inaccuracies.

Xiangxi’s industrial camera lenses excel in distortion control, with most lenses keeping distortion under 0.2%, ensuring precise imaging results.

When selecting an industrial camera lens, key parameters like focal length, aperture, sensor size, pixel count, depth of field, and distortion must be considered. These directly affect the quality of the images and the accuracy of inspections.

these are some key factors to consider when selecting an industrial camera lens. We hope these 3D printing tips help you make more informed decisions. If you’re looking for more 3D printing tips, be sure to visit our website for additional insights and updates.Xiangxi’s lens lineup, with its top-tier performance and accurate configuration, provides perfect visual solutions for industrial inspections and 3D scanning. Whether you’re working on high-precision 3D modeling or complex 3D inspection tasks, Xiangxi’s industrial camera lenses offer reliable visual support for all your needs.

Subscribe Our Channel

Xiangxi Intelligent technology is a national high-tech enterprise focusing on the core components of micro and nano 3D machine vision. We have the core hardware design and development capabilities, parts and finished product manufacturing capabilities and professional software development capabilities of 3D machine vision. We have developed several machine vision products which include 3D AOI core module, 3D structured light, structured light 3D camera, structured light 3D scanner and structured light 3D inspection machines, and we have more than 20 core technology intellectual property rights such as invention patents and software copyrights.