When it comes to industrial measurement, traditional tools like calipers and coordinate measuring machines (CMMs) get the job done—most of the time. But when you’re working with soft, flexible materials like silicone earbud cases, the game changes. Contact-based measurements can cause pressure-induced deformation, leading to inaccurate data and slow, inefficient workflows in reverse engineering.

So, what’s the smarter alternative? High precision 3D scanner. Thanks to their non-contact scanning and rapid, full-surface reverse engineering capabilities, these structured light scanner handle delicate materials with ease—all while simplifying the prep work before scanning. In this article, we’ll dive into these two major advantages and explain why structured light scanners are your go-to solution for measuring soft objects.

Non-Contact Scanning: Say Goodbye to Deformation

Soft materials like silicone are easily distorted under pressure. Even slight contact during measurement can cause dents, stretches, or compressions, leading to inaccurate data. That’s where high precision 3D scanners shine. By using non-contact reverse engineering technology, they capture an object’s true shape without ever touching it.

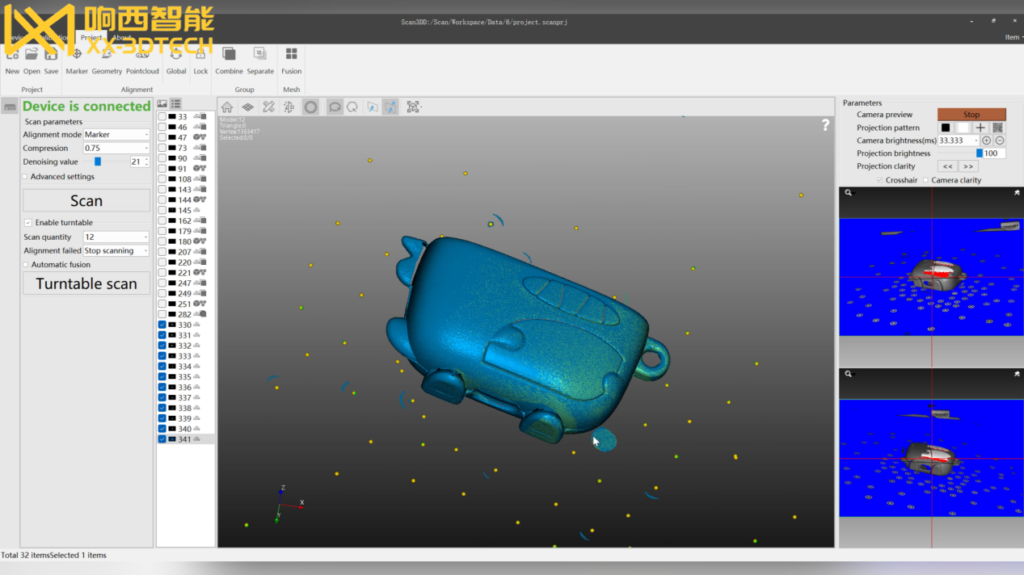

Take a silicone earbud case, for example. Traditional CMMs require constant recalibration and manual positioning—time-consuming and error-prone. In contrast, a high precision 3D scanner uses DLP structured light technology to capture tens of millions of surface data points at micron-level accuracy, all without any physical contact. With structured light scanner, even complex curves and soft materials are scanned flawlessly, ensuring the resulting 3D model is a perfect match to the original.

Full-Surface Reverse Engineering: Boosting Both Speed & Accuracy with Structured Light Scanner

Traditional measurement tools work point by point—a slow process that often misses fine details. Structured light scanner, however, use full-surface reverse engineering, capturing an object’s complete geometry in as little as 1-2 minutes. The result? Over 10x faster data collection compared to conventional methods.

Let’s go back to the earbud case example. Imagine trying to measure tiny ventilation holes or intricate curves with calipers or a CMM—you’d only get partial data, and it would take forever. A high precision 3D scanner, on the other hand, leverages smart algorithms to generate a complete 3D model in just a few clicks. Plus, since the entire surface is scanned at once, there are no stitching errors, ensuring consistent accuracy throughout the model—ideal for both reverse engineering and quality control.

From Point-by-Point to Full-Surface: Cut Costs & Boost Efficiency

High precision 3D scanners don’t just make life easier—they make it cheaper and faster, too. By eliminating the limitations of contact-based tools and switching to non-contact, full-surface scanning, you get:

- Zero deformation–Structured light scanner offers Accurate, reliable data without costly rework.

- Minute-level reverse engineering– Shorter development cycles and faster time-to-market.

From simplified structured light scanner to smarter prep work, these scanners help businesses streamline their workflows and stay ahead of the curve.

Ready to experience the power of high precision 3D scanners?

Visit our official website and follow us on our platforms for more expert tips. Got questions or need a tailored solution? Reach out today—let’s make innovation your competitive edge!

Subscribe Our Channel

Xiangxi Intelligent technology is a national high-tech enterprise focusing on the core components of micro and nano 3D machine vision. We have the core hardware design and development capabilities, parts and finished product manufacturing capabilities and professional software development capabilities of 3D machine vision. We have developed several machine vision products which include 3D AOI core module, 3D structured light, structured light 3D camera, structured light 3D scanner and structured light 3D inspection machines, and we have more than 20 core technology intellectual property rights such as invention patents and software copyrights.