In the previous installment, we explored some impressive applications of Blu Tack in the field of 3D scanning. It’s undeniable that this 3D scanning tool offers certain conveniences and advantages for scanning tasks. While Blu Tack is a useful 3D scanning tool, the best 3D scanners on the market might provide more accurate results for fine details.

Today, let’s dive deeper into the problems Blu Tack may encounter during the 3D scanning process and discuss some 3D scanning tips. By doing so, we can make more informed and strategic use of Blu Tack as a scanning solution to enhance the quality and efficiency of 3D scanning.

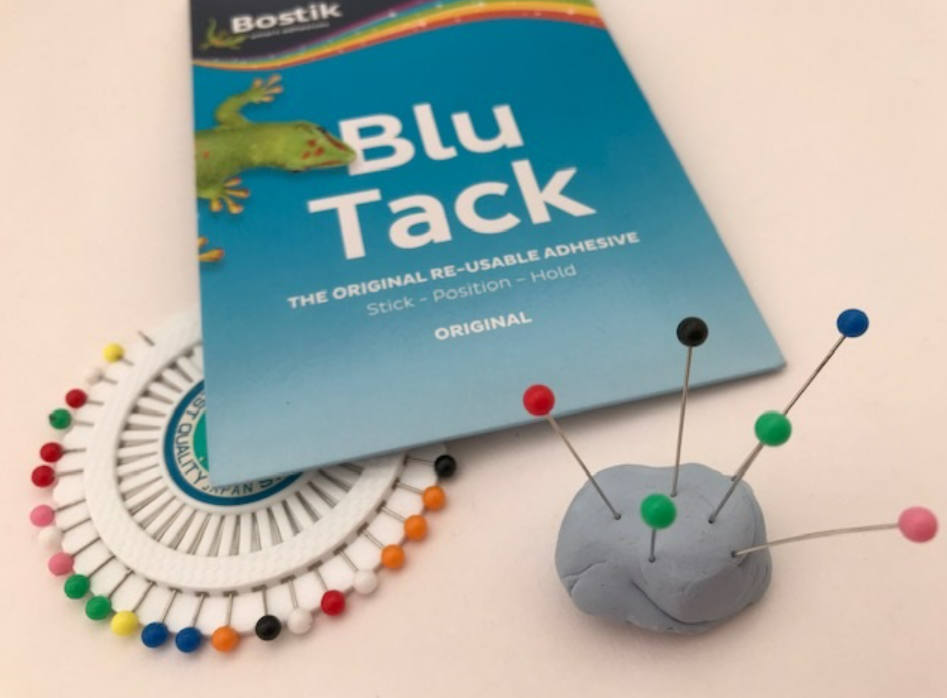

Tips for Working with Blu Tack

Compatibility Issues

When Blu Tack encounters certain special surfaces, such as specific plastics or objects coated with special coatings, it’s like two people with incompatible personalities meeting—there may be a chemical reaction or a poor adhesion effect. In such cases, following 3D scanning tips for dealing with these surfaces can help ensure a better scanning solution to avoid issues during the process.

Environmental Adaptability Challenges

Except compatibility issues, environmental factors are also important an 3D scanning tip. Though intangible, they significantly affect the performance of Blu Tack. Humidity and temperature create a trade-off between flexibility and adhesion for Blu Tack.

Considering in high humidity environments, it may absorb excess moisture, becoming damp and affecting its original adhesive properties.

Extreme temperatures, can also alter its texture and adhesion also change. As a 3D scanning tool, Blu Tack is much like the principle of thermal expansion and contraction, making scanning difficult to maintain stable performance, which could interfere with scanning accuracy.For more precise results, the best 3D scanner may be more reliable in maintaining accuracy under challenging conditions.

Limitations in Detail Capture

The last 3D scanning tips requires precise capture of every detail, which can be challenging for Blu Tack. When dealing with objects with fine features or small gaps, it’s like a clumsy craftsman, unable to handle delicate tasks.

This is especially true when the object needs to stay upright or at a specific angle, Blu Tack may not be the best scanning solution. Instead, as a 3D scanning tool, it could provide sufficient support, but still might leading to incomplete or inaccurate scans.

While Blu Tack aids stability for small to medium objects, the best 3D scanner are essential for large-scale or complex scans to maintain quality and accuracy.

If adhesion is hard or a reaction occurs, a thin plastic film or other test object can be placed between Blu Tack and the object. In high humidity, store Blu Tack in a sealed container and take it out quickly when needed, using a dehumidifier during application.

For temperature fluctuations, it’s advisable to choose a stable environment whenever possible. If necessary, preheat or cool down in advance. When handling detailed objects, divide Blu Tack into small pieces and place them precisely is a great scanning solution. When a specific angle is required, use adjustable stands or clamps to assist in securing with Blu Tack.

3D scanning tips for Using Blu Tack

– Test on Special Surfaces – Blu Tack can be the best scanning solution on plastic coatings.

– Protect Blu Tack from Humidity – Use a dehumidifier to keep Blu Tack stable.

– Find a Stable Spot – Avoid temperature fluctuations for best results, allowing the best 3D scanner to capture the most accurate details.

– Break it Small for Details – Use small pieces for precision.

– Flexibility for Custom Angles– Mold it to adjust objects to desired angles.

– Easy to Clean – Blu Tack leaves no mess behind, making cleanup a breeze.

Above all 3D scanning tips, we can see that Blu Tack is a handy 3D scanning tool, but it’s not the only scanning solution. When scanning with Blu Tack, it’s important to recognize that while it’s a great option, the best 3D scanner may provide superior results, especially for high-precision applications. We encourage readers to share your experiences and stories with Blu Tack.

Let’s explore and learn together how to better utilize this 3D scanning tool and enhance our 3D scanning tips!

Ultimately, choosing the best 3D scanner for your specific needs can make a huge difference in the quality and boost scanning accuracy of your process. If you’re looking for a scanner that offers precision, versatility, and ease of use, we encourage you to explore our selection of the best 3D scanners available. Visit our website for more details on how to enhance your 3D scanning experience!

Subscribe Our Channel

Xiangxi Intelligent technology is a national high-tech enterprise focusing on the core components of micro and nano 3D machine vision. We have the core hardware design and development capabilities, parts and finished product manufacturing capabilities and professional software development capabilities of 3D machine vision. We have developed several machine vision products which include 3D AOI core module, 3D structured light, structured light 3D camera, structured light 3D scanner and structured light 3D inspection machines, and we have more than 20 core technology intellectual property rights such as invention patents and software copyrights.