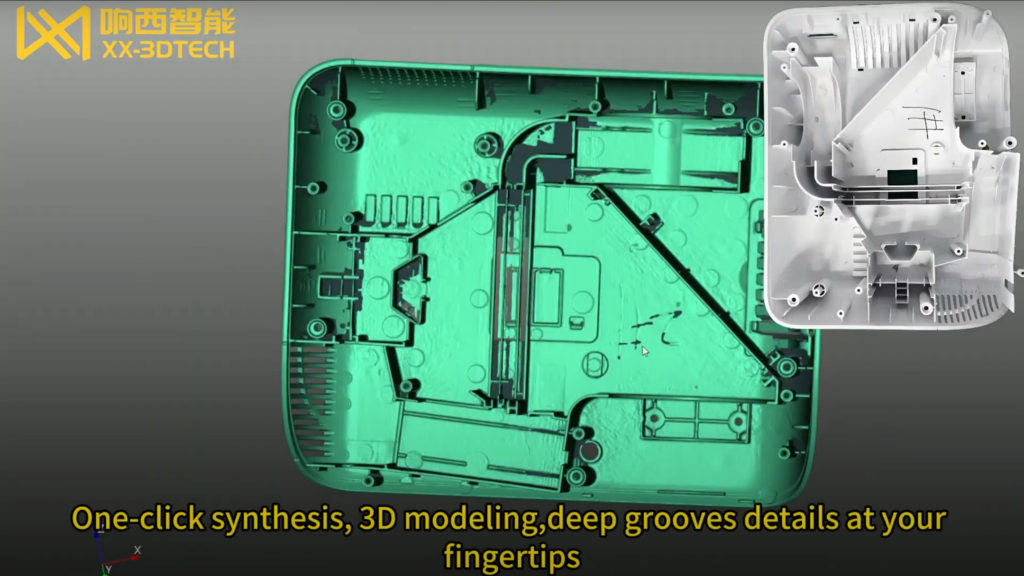

3D Scan deep grooves can be challenging, but with the right approach, it becomes a straightforward process in reverse engineering. The key lies in making sure your industrial 3D scanner is properly set up and your scanning technique is on point. First and foremost, your industrial 3D scanner needs to have a depth of field that exceeds the depth of the groove itself. This is crucial for capturing high-quality 3D point clouds and ensuring that your 3D models are precise. If your scanner’s depth of field falls short, the intricate details you need to capture may be missed. Let’s break down the three essential steps to help you master scan deep grooves like a pro.

Step 1: Start with a Vertical Scan

The first step to successfully scan deep grooves are positioning the scanning area vertically in relation to your industrial 3D scanner. This initial scan aims to capture the center and surrounding features of the groove, ensuring that the bottom is clearly defined. It’s essential to avoid any shadows on the scanning area at this stage. The vertical scan lays the foundation for your subsequent scans, although be mindful that the edges of the groove may still be challenging to capture at this point.

Step 2: Tilt Left for Details on the Right

Next, you’ll want to tilt the scanning area to the left relative to the scanner’s camera. This tilt helps to eliminate any shadows on the right side of the groove, ensuring that the details of the right edge are captured clearly. In your camera preview, make sure the right side of the groove is fully visible. This tilt will allow you to capture the finer details of the right bottom edge, filling in any gaps left from the vertical scan. You’ll achieve this with a single pass of 3D point cloud scanning.

Step 3: Tilt Right for Details on the Left

In this step, you’ll perform a similar tilt but to the right. This ensures that the left side of the groove is illuminated properly, with no shadows blocking important details. Again, check your camera preview to ensure the left bottom edge is visible and captured accurately. This rightward tilt completes the scanning process, ensuring that all areas of the groove are captured and no details are missed in reverse engineering.

3 Essential Steps for Perfect scan deep grooves:

- Vertical Scan: Position the scanning area vertically in front of your industrial 3D scanner. This step ensures you capture the center and bottom of the groove with accuracy, providing a solid base for your scan.

- Tilt Left: Tilt the scanning area to the left to capture the right side of the groove without shadows. Ensure the right edge is visible in your camera preview for complete data.

- Tilt Right: Tilt the scanning area to the right, mirroring the previous step, to fully capture the left side of the groove. Check your camera preview to ensure the left edge is clearly visible and properly scanned.

No Shadows, No Gaps: Throughout the process, it’s crucial to ensure that your camera preview is clear and that you’re capturing the entire groove with no shadows or gaps. This guarantees that every detail is captured precisely, ensuring a flawless 3D model.

Accuracy in Scanning for reverse engineering

When scanning for reverse engineering, capturing the fine details of scan deep grooves is paramount. The accuracy of your 3D scan directly impacts the quality of the model you’re creating, which will ultimately affect the design and manufacturing processes that follow. By mastering the scan deep grooves techniques mentioned above, you can produce high-quality 3D point cloud data that forms the foundation for any reverse engineering project.

With the right scanning techniques and a capable industrial 3D scanner,scan deep groove no longer has to be a complicated task. Even the most intricate grooves can be captured with pinpoint accuracy, unlocking endless possibilities for industries ranging from manufacturing to design.

Ready to Take Your 3D Scanning to the Next Level?

At Xiangxi Intelligent Technology, we offer the scanning tools and expertise you need to elevate your digital manufacturing processes. Stay updated with the latest tips and innovations by following us on our website and other platforms. If you’re interested in learning more or need assistance with your scanning projects, don’t hesitate to reach out. Let’s unlock the full potential of your 3D scanning!

Subscribe Our Channel

Xiangxi Intelligent technology is a national high-tech enterprise focusing on the core components of micro and nano 3D machine vision. We have the core hardware design and development capabilities, parts and finished product manufacturing capabilities and professional software development capabilities of 3D machine vision. We have developed several machine vision products which include 3D AOI core module, 3D structured light, structured light 3D camera, structured light 3D scanner and structured light 3D inspection machines, and we have more than 20 core technology intellectual property rights such as invention patents and software copyrights.