Struggling on 3D scanning large objects or curved, irregularly shaped objects with precision? You’re not alone. Capturing every 3D scan detail can be tricky, but with the right techniques, you can achieve flawless results. In this guide, we’ll break down the fundamentals of industrial 3D printing and show you how segmented scanning and intelligent 3D stitching can make high-precision 3D modeling a breeze. Whether you’re an engineer, designer, or a 3D printing enthusiast, these expert tips will help you elevate your 3D printing game!

How Scanners Work: 3D Scanning Large Objects into Digital Models

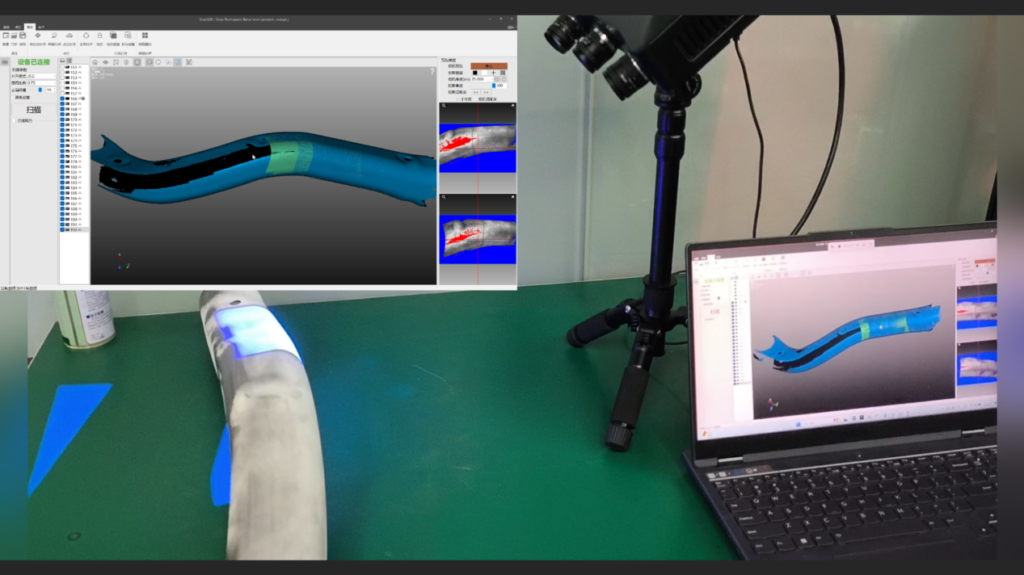

Ever wondered how 3D scanners transform large objects into digital models? It all starts with structured light projection—the 3D scanner emits a DLP pattern onto the object, capturing surface data as a dense point cloud. These points are then connected into a mesh, ultimately forming a detailed 3D stitching model.

However, when scanning large objects or irregularly shaped objects like curved steel pipes, a single scan is rarely enough to capture every large object’s detail. That’s where segmented scanning comes in—mark the object into multiple sections and scanning them individually ensures full coverage and high accuracy.

Segmented Scanning: Capturing Large Object Detail with Precision

When scanning large objects, segmented scanning is key to achieving high-accuracy 3D models. Here’s how you can optimize the process:

Step 1: Scanning Large Objects into Segments

- Subdivide the object into smaller sections based on your 3D scanner’s coverage area for segmented scanning.

- Ensure that adjacent scans overlap by 20%-30%—this overlap is crucial for accurate 3D stitching later.

Step 2: Ensure Clear Overlapping Features

- Each segmented scanning should include distinctive overlapping features like textures, edges, or raised structures.

- If the large objects surface are smooth or lacks features, use scanning marker points or reference objects to improve alignment.

Step 3: Use Reference Objects When Needed

- When scanning large objects with multiple featureless sections, place high-contrast marker points or reference objects before scanning.

- This simple technique significantly improves alignment accuracy, reducing errors during the 3D stitching process.

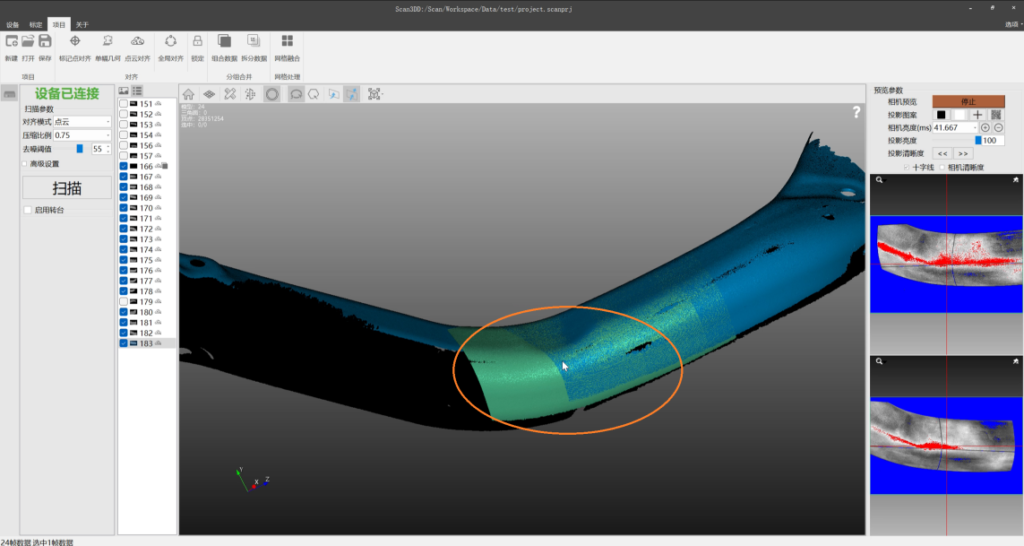

Intelligent 3D Stitching: Seamlessly Merging Your Scans

Once you’ve completed your segmented scanning, the next step is to merge them into a single, flawless 3D model. Modern scanners come equipped with intelligent 3D stitching algorithms, which automatically recognize overlapping areas and align the data seamlessly.

For example, when scanning a curved steel pipe, the algorithm will precisely match the front and back sections, ensuring a smooth and accurate final model. This not only boosts efficiency but also minimizes manual corrections, saving you valuable time.

From Scanning large objects to a Perfect 3D Model

With the scans successfully stitched together, it’s time for 3D stitching model refinement:

- Convert the point cloudinto a polygon meshusing professional software.

- Optimize the surface, making scanning large objectssmoother and more realistic.

- Scale, rotate, and inspect the scanning large object model to ensure accuracy before finalizing it for engineering analysis, industrial design, or 3D printing.

Take Your Scanning Skills to the Next Level!

Thanks to segmented scanning and intelligent 3D stitching, scanning large objects or irregular things with high precision is now easier than ever! Whether you’re a beginner or an experienced professional, mastering these industrial scanning techniques will improve both your workflow and final results.

Stay updated with the latest industrial scanning innovations by following our website. If you’re looking for the best tools for industrial 3D scanning and 3D printing, be sure to check out our latest products or contact us for expert advice! 🚀

Subscribe Our Channel

Xiangxi Intelligent technology is a national high-tech enterprise focusing on the core components of micro and nano 3D machine vision. We have the core hardware design and development capabilities, parts and finished product manufacturing capabilities and professional software development capabilities of 3D machine vision. We have developed several machine vision products which include 3D AOI core module, 3D structured light, structured light 3D camera, structured light 3D scanner and structured light 3D inspection machines, and we have more than 20 core technology intellectual property rights such as invention patents and software copyrights.